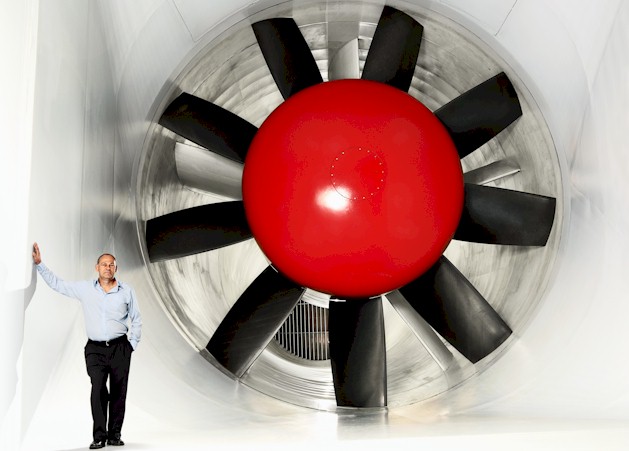

Volvo Car Corporation is the first car manufacturer to own a wind tunnel that fully simulates the airflow around and underneath the car’s body, combined with wheel rotation on a flat road surface.The main idea behind this wind tunnel is the quest for lower fuel consumption and lower carbon dioxide emissions.

Volvo Cars’ wind tunnel was a cutting-edge facility when it was built in 1986 – and 20 years later, after being completely refurbished, it is once again setting the benchmark in the car industry for its precise measurements of aerodynamics.

“Our 20 Million Euro investment is already paying quick dividends. We have succeeded in reducing air resistance in the new Volvo C30 DRIVe by more than 10 percent. This in turn leads to around 3 grams lower CO2 emissions per kilometer,” explains Tim Walker, aerodynamics expert at Volvo Cars.

Translated into fuel consumption, this is a reduction by just over 0.1 l/100 kilometers according to the official EU Combined Cycle. In a real driving situation, however, where speed and therefore air resistance are often higher, the actual saving in fuel can be more than twice as high, that is to say in the region of 0.3 l/100 km.

This means that a driver who covers 15,000 km per year will save about 45 liters of fuel – almost a full tank in a Volvo C30. It’s an economy benefit that is also appreciated by the environment.

“With a firm focus on environmental properties for the foreseeable future, our recently upgraded wind tunnel is going to be a particularly valuable tool. Aerodynamic improvements to the body and underside of the car will help us cut CO2-emissions across the whole model range,” says Magnus Jonsson, Senior Vice President, Research & Development at Volvo Cars.

Source – Volvo