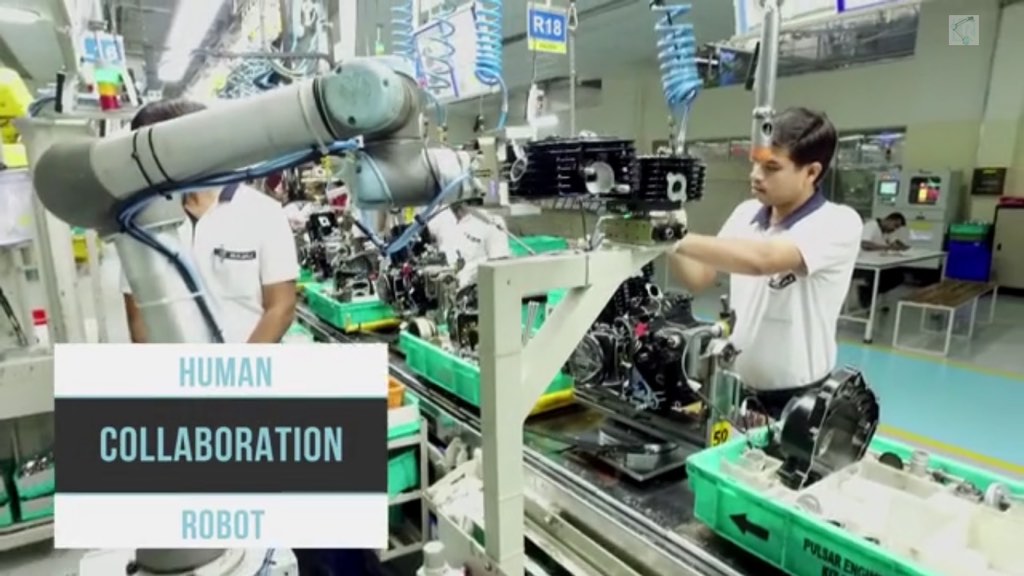

Bajaj Auto is the first company in India to implement the use of collaborative robots in automative assembly lines in India, increasing efficiency in manufacturing.

Times have changed and so has the technology, the old techniques of production no longer exist, as adoption of industrial robots has come into existence and has captured all the industries, which has replaced the human hands by these robots. Bajaj Auto is the first Indian automaker to implement the use of collaborative robots in their production process, they have more than 100 collaborative robots working for them on their shop floors which has helped them become the 3rd largest motorcycle manufacturer in the world.

The bike maker believes that robots can perform tasks at relatively lesser cost and work in a manner that cannot be done with human hands because two-wheeler assembly lines are highly labor-intensive and require a lot of precision. The robots have helped Bajaj ease out processes at shop floors bringing compactness, safety and cost effectiveness at the same time. They claim the robots are useful for companies like Bajaj as the workers have the right tool to carry out repetitive tasks with faultless precision.

The newer generation of robots are smarter, more mobile and adaptable, they bring vital changes on the shop floor, as these robots are designed specifically for performing the tricky jobs in assembly lines. These collaborative robots have considerable capacity to improve the product quality, as implementations are performed with precision and are highly repeated, which automatically improves the production process of a company.

The auto industry is booming like never before, many companies are now bringing in new robotic technologies like collaborative robots to increase production and relief the labor task. Automated robotic system can be used to perform all kinds of automotive tasks on vehicle frames, fenders and under-bodies, as well as other parts of vehicles during production. Bajaj Auto has taken the first step towards automation in India, as it is important for them as well as for the economic growth of the country, a strong manufacturing industry coupled with maximum productivity develops the company as well as the country.

Robots Take Over Automotive Shop Floor At Bajaj Factory

– Industrial robots automate manufacturing at Bajaj Auto

– Bajaj Auto to become the 3rd largest motorcycle manufacturer in the world

– Bajaj Auto has more than 100 collaborative robots working for them on their shop floors