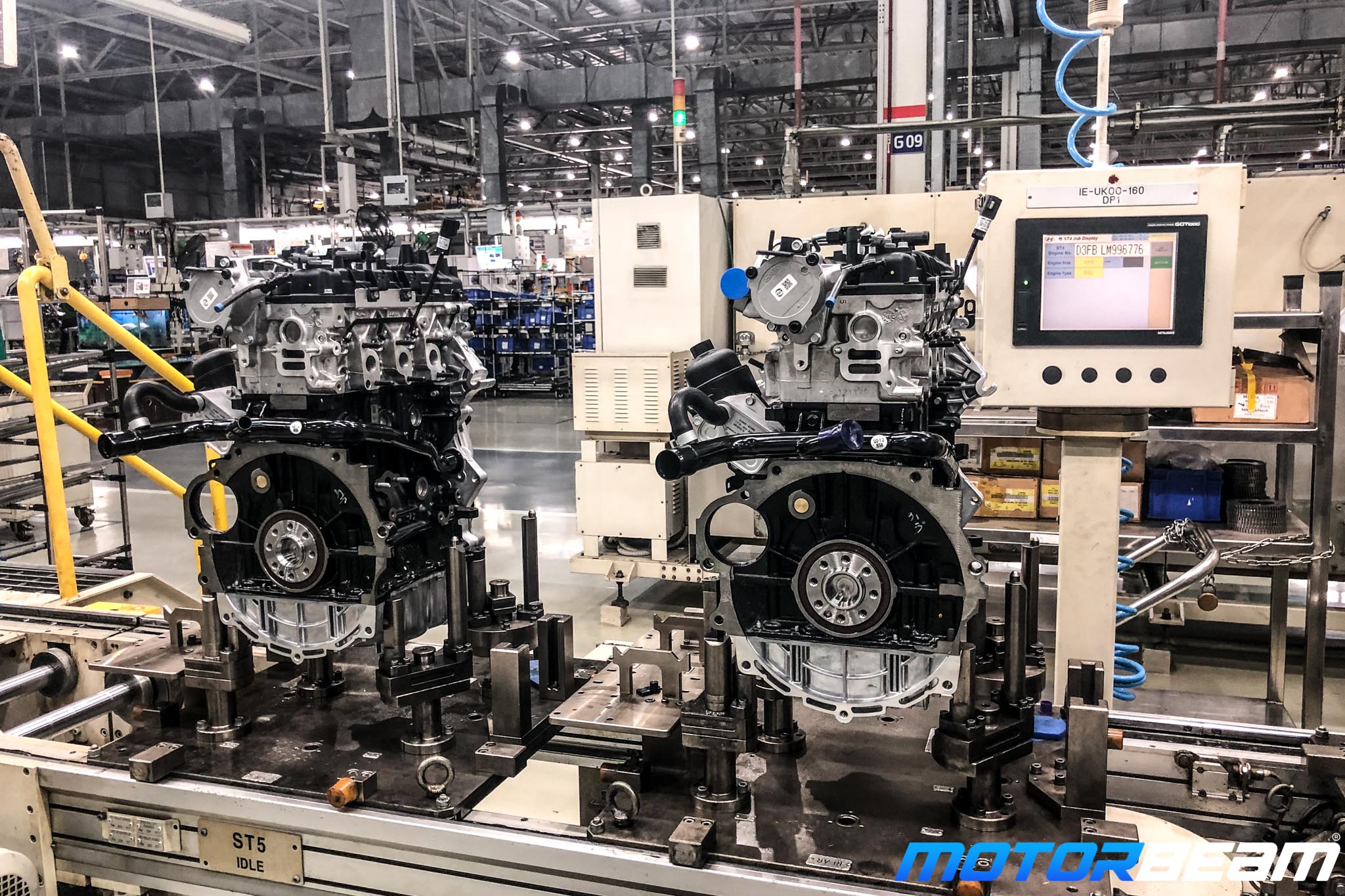

Now that we are done with the body shop, we go to the engine shop to see how the 1.5 diesel is made. This engine is BS6-compliant and is shared with Kia Seltos. After the engine is completely assembled, it passes through the express vision system which detects the presence of external parts in the engine assembly. As many as 45 items are checked within a minute.

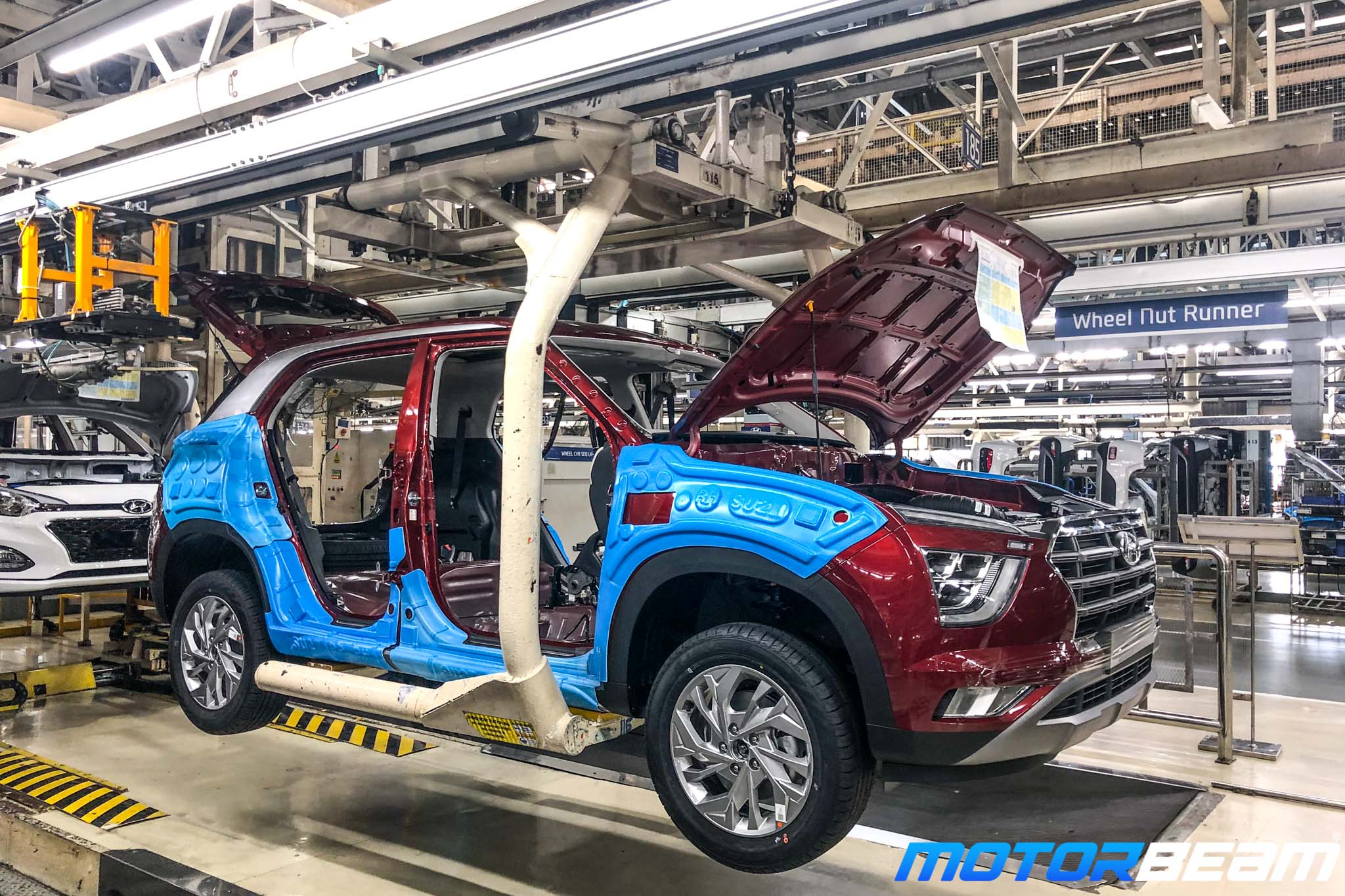

Finally, we go to the assembly shop where the cars are assembled. First the bodyshell is painted and then various components are fitted. The wiring harness is laid out, the trims are installed, parts like the antenna and lights are installed, the engine is fitted and then the entire cabin is put together. Once the car is ready, it goes to the PDI section of the plant.

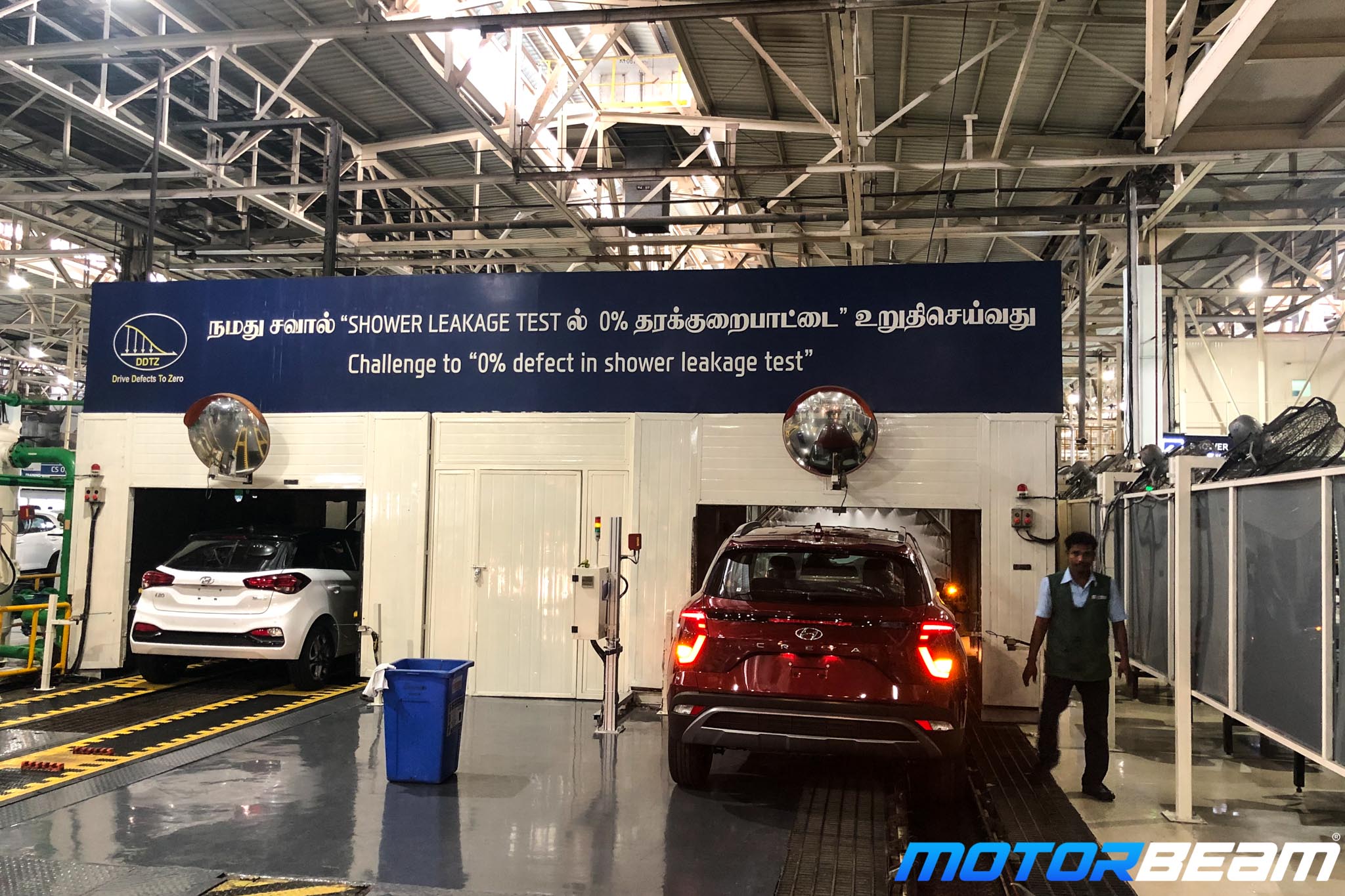

At the PDI section, all the cars are checked thoroughly. There’s a checklist of 150-200 points that Hyundai’s staff has to follow and they meticulously check every car before giving it the go ahead. Once the cars are good to go, they’re driven out of the shop for a road test where they are driven on 17 drive tracks within Hyundai’s plant. The cars are then parked in the stockyard. Soon, the cars get shipped to various dealers and are delivered to their respective buyers.

The 2020 Hyundai Creta gets massive changes on the outside and inside. It gets three engine options – 1.5-litre petrol & diesel and a 1.4-litre turbo petrol engine. The Creta gets a long list of equipment like a touchscreen infotainment system with Apple CarPlay, Android Auto, navigation, voice commands, BlueLink connectivity features, panoramic sunroof, electric parking brake with auto-hold, driving modes, traction control modes, supervision cluster and a lot more. We’ll be testing the 2020 Hyundai Creta later this month.